Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

During the extrusion process of producing profiles, if there are air holes with material leakage, and at the same time the torque of the extruder increases, what is the cause? How should it be solved?

During the extrusion process of producing profiles, if there are air holes with material leakage, and at the same time the torque of the extruder increases, what is the cause? How should it be solved?

During the extrusion process of producing profiles, if there are air holes with material leakage, and at the same time the torque of the extruder increases, what is the cause? How should it be solved?The main causes are as follows:

①If the feeding speed is too fast, the additional shear heat generated is insufficient to balance the heat required for the increased feeding volume, resulting in poor plasticization.

② If the extrusion speed is too fast, the additional shear heat generated is insufficient to balance the heat loss caused by the shortened residence time of the material in the feeding section and the compression section. As a result, the plastic will not be properly plasticized.

③ When using CPE anti-flexibilizer as the formulation, the amount of processing additives is too low, resulting in poor friction performance of the materials. When passing through the exhaust holes, the plasticization effect is poor.

When the problem of material leakage from the exhaust holes occurs, there may be various causes. One should not make a hasty judgment without thorough analysis. Instead, a comprehensive analysis should be conducted and corresponding solutions adopted.

When the exhaust port emits material and the torque of the extruder increases, the solution to be adopted at this time is:

Reduce the feeding rate or the rotational speed of the screw of the extruder, or appropriately increase the processing additives to improve the plasticizing quality of the materials.

- Information

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- What countermeasures can be taken to improve the dimensional and positional accuracy of profiles during the profile production process?

- How should profile molds be cleaned and maintained?

- What are the corresponding solutions to the phenomenon of grooves and pits on the surface of profiles?

- How should the raw materials be selected in the formula for PVC surface skin core layer microcellular foamed extruded profiles?

- How should the production process of biaxially oriented polyethylene terephthalate (BOPET) film be controlled?

- How should the longitudinal and transverse stretching be controlled when producing biaxially oriented films by the flat film method?

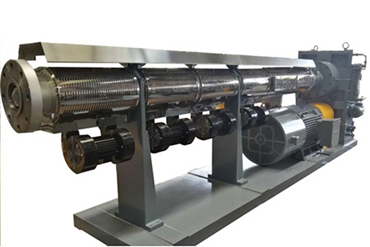

- How should the counter-rotating conical twin-screw extruder be operated for no-load test run?

- What are the characteristics of extrusion blow molding molds?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

-